Pallet wrapping machine repair for all industries

Wiki Article

Discover the Important Advantages of Using a Pallet Wrapping Machine in Your Storehouse Procedures

In contemporary stockroom operations, the adoption of pallet Wrapping devices is becoming progressively crucial. These machines improve the product packaging procedure, boosting effectiveness while substantially lowering labor costs. They also guarantee regular Wrapping quality, which is vital for product security during transit. The benefits prolong past just these aspects. There are extra advantages that can change storage facility monitoring, making it rewarding to discover better.Improved Performance in Packaging Workflow

In the domain name of logistics, effectiveness stands as a paramount goal, and pallet Wrapping makers greatly add to attaining this goal. These devices simplify the product packaging procedure by automating the Wrapping of items, ensuring that products are securely packaged with very little hand-operated intervention. By reducing the time spent on Wrapping, businesses can maximize their workflow, enabling for quicker turn-around times and improved throughput. Additionally, pallet Wrapping machines provide regular Tension and insurance coverage, boosting the security of goods throughout transport. This integrity decreases the risk of product damage, which can cause expensive delays. Overall, the integration of pallet Wrapping equipments right into packaging procedures fosters a much more effective, dependable, and organized method to logistics management.Substantial Labor Cost Financial Savings

While firms venture to lower operational costs, the adoption of pallet Wrapping equipments can cause considerable labor expense financial savings. By automating the Wrapping process, these machines decrease the requirement for manual work, permitting employees to focus on more essential tasks. With the capability to wrap pallets quickly and constantly, fewer workers are called for to finish packaging procedures, leading to reduced pay-roll expenditures. In addition, the makers improve performance as they can operate continually, reducing downtime connected with manual Wrapping. pallet wrapping machine repair. This efficiency equates to faster turnaround times and enhanced general process. Training workers to run these equipments commonly calls for much less time compared to training for hands-on Wrapping strategies, further adding to lowered labor costs in storehouse operations.Enhanced Product Protection Throughout Transit

Reputable and constant Wrapping Quality

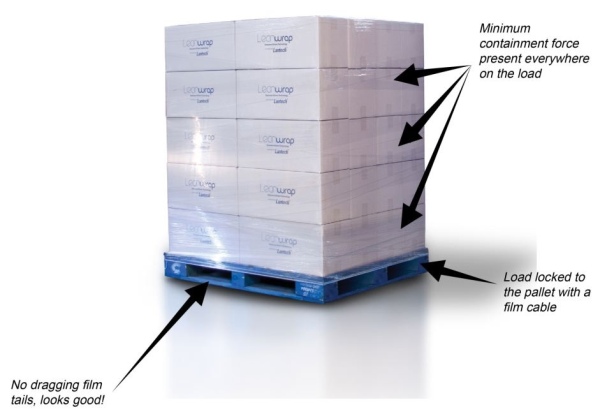

Pallet Wrapping devices provide constant and trustworthy Wrapping high quality, making certain that every pallet is covered consistently despite operator experience. This uniformity decreases the danger of damages throughout transport, as properly wrapped pallets preserve their honesty. The makers apply an excellent quantity of stretch film, minimizing waste and making sure that the load is safeguarded successfully. Unlike handbook Wrapping, which can differ considerably based on the employee's strategy, a computerized process warranties that each pallet receives the same level of protection. This reliability not only boosts the security of products but also simplifies procedures, permitting an extra effective process. Inevitably, the constant Wrapping high quality supplied by these devices leads to enhanced client satisfaction and decreased expenses connected with item loss.Increased Stockroom Space Usage

Effective storage facility space utilization is a vital element in optimizing procedures, and pallet Wrapping devices play a substantial duty in attaining this goal. By firmly Wrapping pallets, these machines lessen the danger of item damages throughout storage and transportation, permitting much more efficient stacking and storage space methods. Improved stability indicates that pallets can be packed greater without jeopardizing security, which takes full advantage of vertical area use. Furthermore, the constant Wrapping process warranties consistent measurements, making it possible for better company and efficient use of available area. This causes decreased aisle width requirements and enables even more item to be kept in the very same location. In general, utilizing a pallet Wrapping equipment enhances area efficiency, adding to structured storage facility procedures and increased performance.Frequently Asked Concerns

What Types of Products Can Be Covered Making Use Of a Pallet Wrapping Equipment?

Numerous items can be covered using go to my blog a pallet Wrapping equipment, consisting of boxes, pallets of food, commercial goods, check my blog and delicate items. The equipment fits varied sizes and shapes, guaranteeing protected packaging for effective transport and storage space.

Just how much Does a Pallet Wrapping Machine Typically Expense?

The cost of a pallet Wrapping equipment usually ranges from $3,000 to $20,000, depending upon functions and capacities. Variables such as automation level and brand name track record can substantially influence the last price.Can Pallet Wrapping Machines Be Integrated With Existing Storage Facility Equipments?

Pallet Wrapping machines can commonly be incorporated with existing storage facility systems, improving efficiency (pallet wrapping machine repair). This integration allows for streamlined procedures, improved stock monitoring, and far better sychronisation with other automated processes, eventually optimizing overall storehouse performanceWhat Is the Upkeep Requirement for Pallet Wrapping Machines?

The maintenance requirements for pallet Wrapping equipments usually include normal evaluations, lubrication of relocating components, and substitute of used elements. Sticking to these methods guarantees peak efficiency and longevity, reducing operational disruptions in storehouse settings.Exist Security Worries When Utilizing Pallet Wrapping Machines?

Safety and security concerns when utilizing pallet Wrapping devices consist of potential injuries from moving parts, inappropriate handling, and inadequate training. Guaranteeing proper safeguards, normal maintenance, and employee education and learning can considerably reduce these threats in warehouse atmospheres

Report this wiki page