Pallet wrapping machine repair for uninterrupted packaging performance

Wiki Article

Exactly How to Make the most of Efficiency With a Pallet wrapping Equipment: Common Repair Tips

Maximizing effectiveness with a pallet wrapping device needs a critical technique to maintenance and repair. Normal checks are necessary to ensure all components operate efficiently. Typical concerns such as irregular film stress and jamming can disrupt procedures. Resolving these issues immediately can improve productivity. Comprehending the subtleties of adjusting stress and maintaining cleanliness is similarly essential. What details steps can be required to guarantee peak efficiency?

Routine Upkeep Checks

Regular upkeep checks are important for making sure the ideal efficiency of a pallet wrapping maker. These checks not just improve the durability of the devices but likewise enhance functional performance. Routine evaluations need to include analyzing the equipment's electrical elements, ensuring that all links are protected and free from rust. The film giving system should be looked for correct positioning and stress to prevent operational disturbances. In addition, lubing moving parts decreases friction and wear, preserving smooth performance. Operators must likewise examine the control panel for any irregularities in readings or functionality. Regular maintenance promotes an aggressive strategy to tools care, inevitably leading to lowered downtime and enhanced performance in the wrapping procedure. Complying with a set up upkeep plan is vital for optimal performance.Troubleshooting Typical Concerns

Replacing Damaged Parts

Replacing damaged parts is vital for preserving the ideal efficiency of a pallet wrapping device. Normal assessments assist identify components that reveal indicators of wear, such as the film carriage, rollers, or drive belts. These components can degrade in time, leading to inefficiencies in wrapping procedures. When substitute is required, it is vital to pick top notch components that match the equipment's specs to ensure compatibility and top efficiency. Technicians ought to comply with the manufacturer's guidelines throughout the substitute process, as incorrect installment can cause more concerns. Additionally, maintaining a supply of commonly needed parts can lessen downtime, permitting quicker fixings and preserving productivity levels. Positive maintenance and timely replacements are crucial to prolonging the maker's life-span.Readjusting Stress and film Setups

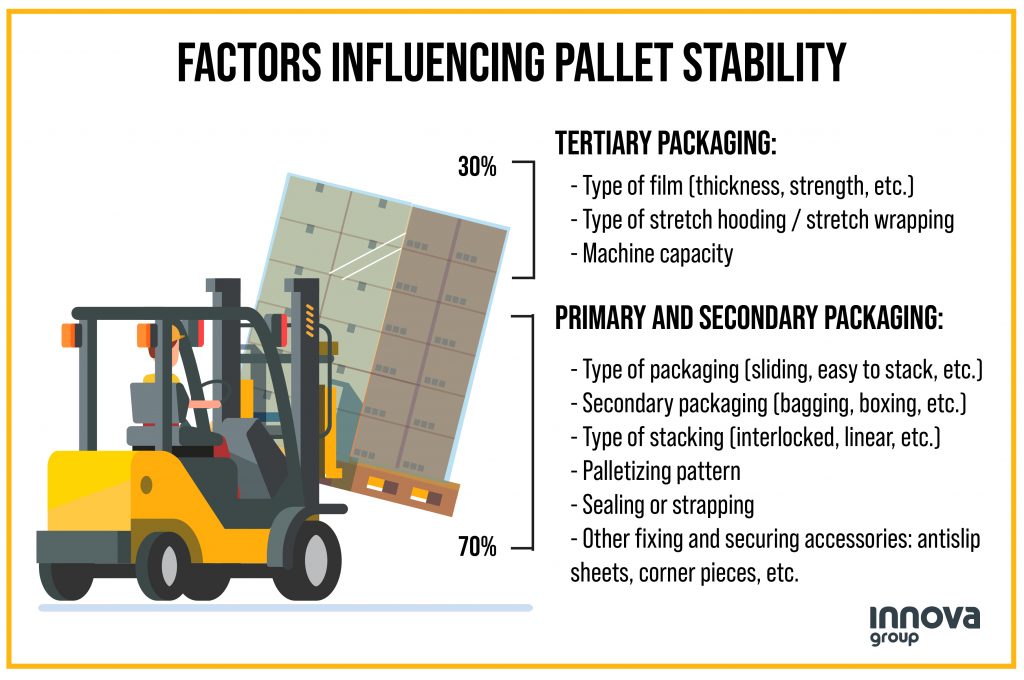

Keeping excellent efficiency of a pallet wrapping equipment expands past changing worn-out parts; it additionally entails make improvements the stress and film setups. pallet weblink wrapping machine repair. Correct tension is essential for attaining optimum load security throughout transport. If the stress is as well tight, it may harm the load, while not enough tension can result in loose wrapping and prospective shifting. Operators needs to on a regular basis examine and change the tension settings according to the details needs of the load being wrappedIn addition, choosing the right film type and thickness is vital for guaranteeing effective wrapping. Thicker films offer improved stamina yet may call for greater tension setups. On the other hand, thinner films might be a lot more economical however can compromise load safety if not correctly tensioned. Regular adjustments will make the most of efficiency and decrease material waste.

Keeping the Machine Lubricated and tidy

Although typically overlooked, keeping the pallet wrapping maker clean and lubricated is necessary for guaranteeing peak efficiency and durability. Routine cleansing aids avoid the build-up of dust, debris, and deposit that can hinder mechanical features. It is suggested to wipe down surface areas and eliminate any kind of built up materials after each usage. Furthermore, correct lubrication of moving components minimizes rubbing, minimizes wear, and expands the lifespan of the device. find out Operators ought to get in touch with the maker's standards for advised lubricating substances and maintenance routines. Executing routine inspections to identify any type of indications of corrosion or deterioration can likewise protect against even more significant concerns down the line. Abiding by these techniques will certainly not just boost efficiency but also advertise secure operation of the pallet wrapping machine.Regularly Asked Questions

How Frequently Should I Replace the Pallet wrapping film?

The frequency of replacing pallet wrapping film depends upon usage and wear. pallet wrapping machine repair. Normally, it must be changed when indicators of damage, tears, or extreme stretching take place, making certain suitable efficiency and protection of the wrapped itemsCan I Make Use Of Different Kinds Of Films With My Device?

Different types of films can normally be made use of with pallet wrapping equipments, but compatibility depends on the device's requirements. Users need to get in touch with the maker's standards to ensure peak performance and prevent prospective damage to the equipment.What Safety Preventative Measures Should I Take While Operating the Device?

When running a pallet wrapping equipment, one need to put on suitable individual protective tools, warranty appropriate training, maintain more helpful hints a clear work space, and on a regular basis check the machine for any kind of prospective hazards to assure secure operation.Exactly how Do I Train New Employees to Make Use Of the Pallet wrapping Device?

To train new employees on the pallet wrapping device, one need to supply comprehensive demonstrations, in-depth handbooks, and hands-on technique sessions. Regular assessments and feedback will certainly improve their skills and ensure secure, efficient operation.What Are the Indications That My Maker Needs Specialist Servicing?

Indicators indicating a requirement for expert maintenance include unusual noises, irregular wrapping, frequent mistake messages, and visible endure components. Prompt interest to these issues can stop further damage and warranty peak device efficiency.Regular maintenance checks are crucial for ensuring the optimum performance of a pallet wrapping machine. Replacing damaged components is vital for preserving the suitable performance of a pallet wrapping device. Preserving excellent performance of a pallet wrapping maker prolongs beyond changing worn-out components; it also includes make improvements the stress and film settings. Typically neglected, maintaining the pallet wrapping maker tidy and lubed is crucial for making sure peak performance and durability. Various types of films can normally be utilized with pallet wrapping machines, yet compatibility depends on the maker's requirements.

Report this wiki page